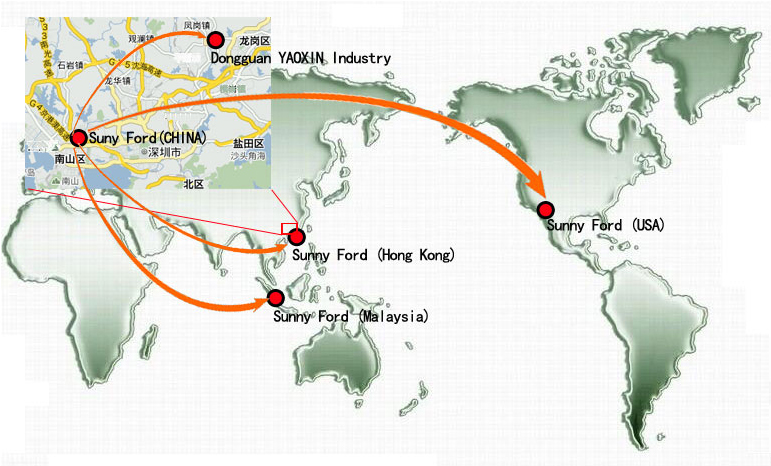

Dongguan Yaoxin Industry Co., Ltd. was registered in Fenggang town, Dongguan City in April 2011. The factory covers an area of more than 70000 square meters, with 7 standard factories and 6 staff dormitories. The company's existing products are widely used in communication cabinet, all kinds of hardware stamping (such as TV hardware, automobile hardware), LED screen box and other fields, while specializing in the production of flat-panel TV (including LCD, plasma, LED) hangers and building hardware. The company has 1 German TRUMPF laser laser machine, 6 Japanese Amada servo CNC punches, 14 Japanese Amada bending machines, 3 Japanese Panasonic welding robots, 2 mixed spraying lines, more than 40 Taiwan Xieyi 80t-500t punches in total, of which the punches above 200t are mostly Taiwan Xieyi, Jinfeng and other precision punches; at the same time, it has three dimensional, spectrum tester, salt spray tester, color difference tester Instrument, film thickness tester, HR hardness tester, combustion tester and other professional testing equipment; including product structure design, mold design and production, mechanical processing, stamping, bending, welding, spraying a complete set of sheet metal / metal stamping processing and production.

A company integrating software development, hardware development, sheet metal structure design, manufacturing and precision stamping die design and manufacturing.

It has passed ISO9001 international quality system certification, ISO14001 international environmental system certification, IATF16949 automotive industry management system certification, passed ISO/IEC27001 information security management system certification in 2018, and passed ISO45001:2018 occupational health and safety management system certification in 2019.

Our Advantage

Low cost and high quality: Proactively provide cost reduction suggestions; actively cooperate with customers' cost reduction solutions; continuously improve process and quality for quality improvement.

For customers: a dedicated cross-sectoral team to support customers; feedback on customer needs and issues within 24 hours; provide each customer with the highest quality service with a positive attitude; able to meet customers' short-term capacity change needs.

Superb Quality Tight process, precise inspection, layer-by-layer inspection |  Flexibility Extremely flexible and adaptable |  Stability Adapt to the environment and ensure stable operation |

Strive to create the best quality products for our customers

Provide better service to customers, create greater value for customers, and build a broad platform for employees

Honest, fair, steady, creative

Diligent, rigorous, truth-seeking, pragmatic

Full participation, excellence, customer satisfaction, continuous improvement

Compliance with regulations, make good use of resources, maintain the environment, and continuously improve

Integrity and law-abiding, people-oriented, safety first, continuous improvement

Strengthen consciousness, standardize behavior, data confidentiality, complete information

Quality is the first, reputation is the most important, management is the basis of service.